As a business working to a tight production schedule, every cog in your business machine needs to be working in unison. From your employees and the production line to your marketing team, sales and procurement officers, every element of your business must complement the other in order to drive results and increase your market share.

Regrettably, as an OEM, not all facets of your business can feel like they’re in your control. In fact, one of the main sources of contention and problems within original equipment manufacturer models are suppliers. Unreliable suppliers can cause all kinds of issues within your enterprise, and not just on the production line. Poor quality parts, late deliveries and wrong orders can leave you struggling to maintain contracts with your own clients, making you the weak link in the supply chain.

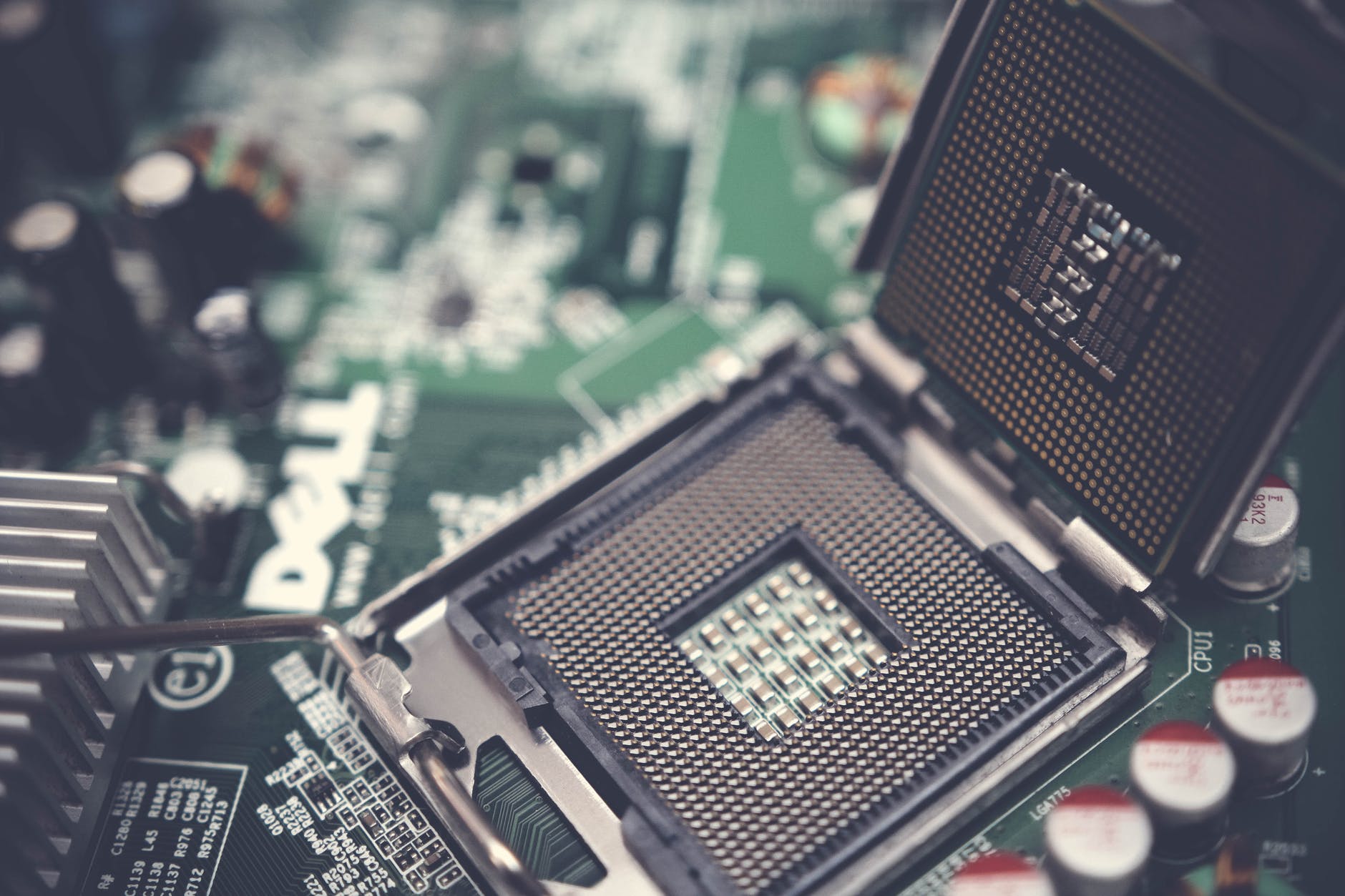

It’s not always easy to let go of your suppliers, especially if you’ve worked with them for a lengthy period. However, if their standards are meeting your requirements, OEMs are encouraged to look elsewhere for their parts – you’ll find an inventory of Rabbit Semiconductors Inc electronic components, here. Now we’ll explore the worrying signs that you need a new components supplier. Read on to find out more.

You’re In the Dark With Poor Communication

You’re part of a supply chain, and you need your order promptly, so you can meet the agreed details of your contracts with your clients. Perhaps you want to make a change to your order, or there’s a problem with the delivery. Whatever the issue, it’s vital that the lines of communication between you and your suppliers are open and helpful. If you’re struggling to get hold of your merchants, or are left completely in the dark with delivery dates, problems are going unresolved, emails are unanswered and phone calls are not returned, find yourself a new supplier – now!

Product Failures and Low-Quality Designs

Are the products you’re receiving meeting your standards? When component parts fail after a few weeks, or low-quality designs mean that you’re having to apologise to your clients when their finished products break, then it’s time for a new supplier. Sending broken components back, rectifying mistakes and broken products you’ve sent out to your clients will be costing you a fortune in time and money. As well as damaging your reputation as a high-quality OEM.

Your Inventory Levels Are Out of Control

When a component parts supplier isn’t sticking to your schedules, sending you the right parts, or messing up orders, then your inventory levels will start to overwhelm you. This means potentially carrying too much inventory and costing you a fortune in storage and management. Alternatively, if they’re failing to send the right amount of parts, then your productivity levels will suffer, and you’ll lose more clients who don’t think you can keep up with demand.

And Finally

Spending is Out of Control

If your procurement team is struggling to keep costs down and stick within budget then it’s time to look elsewhere for your component parts. Consider using a global marketplace to source your electronic parts.